Zvimiro zvetungsten carbide rod uye mashandisirwo ayo Tungsten carbide kana simende carbide ine akawanda emhando yepamusoro senge kuomarara kwepamusoro, kusimba kwakanaka, kupfeka kwakanaka uye kusagadzikana kwekuora uye kugadzikana kwakadzikama pasi petembiricha yepamusoro kunyangwe pa500 ° C.Inoramba isina kuchinjwa uye kunyange pa1000 ° C inowana kuoma kwakanyanya.

Cemented Tungsten Carbide tsvimbo inosiirwa muHIP Furnace uye yakagadzirwa ne100% mhandara mbishi zvinhu izvo zvinosanganisira WC neCO.

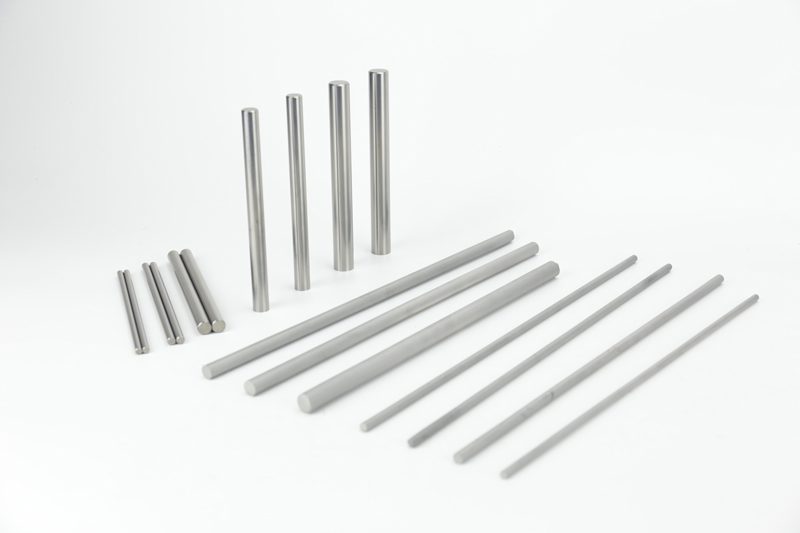

Panowanzove nemhando nhatu dzesimende tungsten carbide tsvimbo sePCB tsvimbo, blank rod, uye tsvimbo.

Ruzhinji rwemashandisirwo ayo ari mukugadzirwa kwemidziyo yekucheka simbi, pamwe nehuni, mapurasitiki, uye zvimwe zvinhu uye maindasitiri anoda huwandu hwakaoma hwekuomarara, kusapfeka, uye kusagadzikana kwekuora.

Tungsten carbide rod ine huwandu hwehumwe hunhu hwakasarudzika, hunosanganisira huwandu hwakanyanya hwekuoma uye kusimba, kuramba kukuru kupfeka uye ngura, uye kugadzikana kunoshamisa kunyangwe paine tembiricha.Simbi yekukanda, simbi dzisina ferrous, mapurasitiki, makemikari fiber, simbi isina tsvina, uye yakakwirira manganese simbi zvinongori zvimwe zvezvinhu zvinogona kucheka nechombo ichi.Pamusoro pezvo, inogona kushandiswa kugadzira maturusi ekuchera, maturusi emigodhi, zvipfeko zvekupfeka, mabheji chaiwo, mhuno, uye mold dzesimbi, pakati pezvimwe zvinhu.

Heano mamwe matanho ekugadzira tungsten carbide tsvimbo.

1) Giredhi Dhizaini

Giredhi rakagadzirwa nefekitari yedu: SK10, SK30, SK35B, SK35, SK45 nezvimwe.

Kurudzira Giredhi rakakodzera rekushandisa tungsten carbide rods.

2) RTP Bhora Milling

Iyo bhora inokuya chigayo inokwanisa kugadzira hupfu hwechero saizi yezviyo, kusanganisira yakatsetseka uye yekupedzisira-yakatsetseka kubva kune yakasanganiswa zvinhu zveWC poda, cobalt hupfu, uye doping zvinhu.

Kupfapfaidza -Drying Process

Kuti uve nechokwadi chekuti zvinhu zvakachena zvachose, prilling tower inopfapfaidzwa nekuomesa spray.

3) Extrusion kana Direct Kudzvanya

2 nzira dzakasiyana dzekugadzira iyo carbide tsvimbo.

4) Kuomesa Maitiro

5) Sintering

Iyo blade inobata kurapwa kwekupisa patembiricha ye1500 degrees Celsius kwemaawa gumi nemashanu.

6) Machining

Mutengi anoda H5 / H6 pasi pevhu, ipapo isu tichagadzira carbide tsvimbo nekukuya kusina centre.

7) Quality Test and Inspection

Kuedza kutwasanuka, saizi, uye kuita kwemuviri seTRS, Kuoma uye carbide tsvimbo kutaridzika nezvimwe.

8) Packaging

Rongedza carbide tsvimbo muPurasitiki bhokisi rine label pairi.

Nguva yekutumira: Mar-04-2023